After much thought and reflection, I have decided to cease weekly publication of The Creativity Paradox.

Publishing the blog has been a great learning experience and an opportunity to understand the discipline of an unyielding schedule. I hope the readers have enjoyed the posts and found the content useful.

I will leave the existing content in place for anyone who wishes to reference it later. There may be additional posts in the future, but that is a decision for another day.

Best wishes,

Dave

Wednesday, August 7, 2013

Saturday, July 27, 2013

Construction Paper

If you are the type who believes that printers should stick to putting ink on paper, here is a 3D printer for you! The Iris printer from Mcor Technologies uses an Epson inkjet printer and a stack of 20 lb sheets of paper to build full color 3D parts that look and feel like wood.

In the selective deposition lamination (SDL) process developed by Conor and Fintan MacCormack, each sheet of paper is printed in the area that will become the edge of the final part. The paper is thin enough to allow the ink to be absorbed through the entire thickness of sheet.

Next, the first sheet is placed on the build platform and a layer of glue is applied in the area that represents the solid part of the first layer of the model. The paper is sliced along the printed outline and the next sheet is dropped into position. The process continues, layer after layer, until the entire part is constructed.

When the model is finished, the excess paper is pulled away to reveal the finished part. The finished items are light, strong and brilliantly colored.

You might also like:

Additive Manufacturing Pioneers

It Started with Stereolithography

Changing the World with a Glue Gun

In the selective deposition lamination (SDL) process developed by Conor and Fintan MacCormack, each sheet of paper is printed in the area that will become the edge of the final part. The paper is thin enough to allow the ink to be absorbed through the entire thickness of sheet.

Next, the first sheet is placed on the build platform and a layer of glue is applied in the area that represents the solid part of the first layer of the model. The paper is sliced along the printed outline and the next sheet is dropped into position. The process continues, layer after layer, until the entire part is constructed.

When the model is finished, the excess paper is pulled away to reveal the finished part. The finished items are light, strong and brilliantly colored.

You might also like:

Additive Manufacturing Pioneers

It Started with Stereolithography

Changing the World with a Glue Gun

Wednesday, July 24, 2013

Capturing More with Less

|

| Image by DrBob via Wikimedia Commons |

The paper, prepared by Felix Heide, Mushfiqur Rouf, Matthias Hullen, Bjorn Labitzke, Wolfgang Heidrich and Andreas Kolb, observes that modern camera optics are complex, heavy and expensive to compensate for the geometric and chromatic aberrations of a single lens. The paper proposes a method to remove the artifacts through a set of computational techniques.

Considering how much the iPhone and Instagram have influenced photography over the last few years, it is fascinating to imagine the impact of capturing perfect images with a single element lens.

Will you be selling your lenses soon?

You might also like:

Cellphone Array Camera

It's About Time

Every Image Possible

Thursday, July 18, 2013

Roads Scholar

I have written before about using time in transit for learning. A few days ago I discovered some news that makes this even easier. Audible.com is now offering access to The Great Courses from The Teaching Company.

In the past, I have been disappointed in the quality of some of the free audio courses that I have found online. And I have been discouraged from The Great Courses because they seemed expensive.

On the other hand, my Audible subscription has been wonderful for listening to books and the ability to exchange one Audible credit for an entire course from The Teaching Company is an incredible value. The course I am currently taking on the French Revolution and the Age of Napoleon is amazing.

What do you want to learn this week?

You might also like:

University on Four Wheels

Books in the Internet Age

Collision of Ideas

In the past, I have been disappointed in the quality of some of the free audio courses that I have found online. And I have been discouraged from The Great Courses because they seemed expensive.

On the other hand, my Audible subscription has been wonderful for listening to books and the ability to exchange one Audible credit for an entire course from The Teaching Company is an incredible value. The course I am currently taking on the French Revolution and the Age of Napoleon is amazing.

What do you want to learn this week?

You might also like:

University on Four Wheels

Books in the Internet Age

Collision of Ideas

Thursday, July 11, 2013

Write to Remember

|

| African Elephant by Terri Williams |

In any week, I see thousands of emails, tweets and status updates. I take the time to read dozens of reports and articles in their entirety. When I am in the car, I am listening to an audio book. The result can be a muddy mixture of disjointed facts that appear to be unrelated.

Writing this blog helps distill those facts into recognizable patterns. Before I can write a coherent sentence, I have to form a coherent thesis. Incomplete or questionable parts of the thesis need to be researched and confirmed. This process of organizing my thoughts both clarifies and reinforces the memories.

What techniques do you use to remember?

You might also like:

The IDE3A Process

Ideas are Like Chili

More Ideas

Thursday, July 4, 2013

Making Paper

On Independence Day, it is fun to remember that paper played a role in the American Revolution. Boston's Liberty Paper Mill, founded in 1770 by Stephen Crane, provided the paper to Paul Revere to print the colonies first paper money.

Later, Crane's son moved west to Dalton Massachussets to open his own paper company. So a visit to the Crane Museum was on my list of things to see while we were in the Berkshires. The museum features scale models to show each of the steps that were involved in making paper in the 19th century.

In 1801, when Zenas Crane launched Crane and Company, almost all of the fiber used for paper came from discarded cotton and linen rags. So the first step in paper making is collecting and sorting the rags.

In 1801, when Zenas Crane launched Crane and Company, almost all of the fiber used for paper came from discarded cotton and linen rags. So the first step in paper making is collecting and sorting the rags.

This is a scale model of a Hollander Beater. The beater would tear apart the rags and break them down into individual cotton or linen fibers.

This is a scale model of a Hollander Beater. The beater would tear apart the rags and break them down into individual cotton or linen fibers.

The fibers are mixed with water and additives to form a slurry of rag pulp. The tanks where the mixing takes place are called chests.

The fibers are mixed with water and additives to form a slurry of rag pulp. The tanks where the mixing takes place are called chests.

The Vatman dips his mould, a framed wire screen, into a vat of pulp. He lifts the mould out of the pulp and shakes it to drain off excess water. The pulp that remains in the screen forms a moist sheet of paper.

The Vatman dips his mould, a framed wire screen, into a vat of pulp. He lifts the mould out of the pulp and shakes it to drain off excess water. The pulp that remains in the screen forms a moist sheet of paper.

The Coucher turns the mould over so the damp sheet of paper adheres to a piece of wool felt. He returns the mould to the Vatman.

The Coucher turns the mould over so the damp sheet of paper adheres to a piece of wool felt. He returns the mould to the Vatman.

The Layboy separates the sheets from the felt and stacks the paper into sets of 144, a quantity referred to as a "post."

The Layboy separates the sheets from the felt and stacks the paper into sets of 144, a quantity referred to as a "post."

Today, paper is made in rolls on machines that do these same steps in a continuous process. The paper is cut into sheets afterward.

You might also like:

17+17>34

Print Can Be Art

Finish Before You Start

Later, Crane's son moved west to Dalton Massachussets to open his own paper company. So a visit to the Crane Museum was on my list of things to see while we were in the Berkshires. The museum features scale models to show each of the steps that were involved in making paper in the 19th century.

In 1801, when Zenas Crane launched Crane and Company, almost all of the fiber used for paper came from discarded cotton and linen rags. So the first step in paper making is collecting and sorting the rags.

In 1801, when Zenas Crane launched Crane and Company, almost all of the fiber used for paper came from discarded cotton and linen rags. So the first step in paper making is collecting and sorting the rags. This is a scale model of a Hollander Beater. The beater would tear apart the rags and break them down into individual cotton or linen fibers.

This is a scale model of a Hollander Beater. The beater would tear apart the rags and break them down into individual cotton or linen fibers. The fibers are mixed with water and additives to form a slurry of rag pulp. The tanks where the mixing takes place are called chests.

The fibers are mixed with water and additives to form a slurry of rag pulp. The tanks where the mixing takes place are called chests. The Vatman dips his mould, a framed wire screen, into a vat of pulp. He lifts the mould out of the pulp and shakes it to drain off excess water. The pulp that remains in the screen forms a moist sheet of paper.

The Vatman dips his mould, a framed wire screen, into a vat of pulp. He lifts the mould out of the pulp and shakes it to drain off excess water. The pulp that remains in the screen forms a moist sheet of paper. The Coucher turns the mould over so the damp sheet of paper adheres to a piece of wool felt. He returns the mould to the Vatman.

The Coucher turns the mould over so the damp sheet of paper adheres to a piece of wool felt. He returns the mould to the Vatman. The Layboy separates the sheets from the felt and stacks the paper into sets of 144, a quantity referred to as a "post."

The Layboy separates the sheets from the felt and stacks the paper into sets of 144, a quantity referred to as a "post."Today, paper is made in rolls on machines that do these same steps in a continuous process. The paper is cut into sheets afterward.

You might also like:

17+17>34

Print Can Be Art

Finish Before You Start

Thursday, June 27, 2013

Manufacturing Matters

|

| Rail service between Lowell and Boston began in 1835. |

These experiences have brought home how important manufacturing has been to our country. In the Civil War, the Union had a greater population and greater manufacturing capacity than the Confederacy. While the link between manufacturing capacity and the ability to make more and better weapons is obvious, the population superiority is also linked to industrialization.

The mill towns like Lowell and Fall River, Massachusetts and the railroad centers of New York and Chicago provided employment and opportunity for a much greater group of people than the agrarian economy of the South. Once the Union was able to mobilize its resources and focus on the war effort, the outcome was inevitable.

|

| Cotton looms in a water driven mill in Lowell, Massachusetts |

In both of the World Wars, the United States was able to play a pivotal role in preserving democracy. Roosevelt's "Arsenal of Democracy" was possible because of the investments made in the late 19th Century and early 20th Century in rail infrastructure, steel mills and vehicle manufacturing.

In times of peace, manufacturing has been the engine that powered the growth of the middle class. Making things provides employment and opportunity for people with wide sets of skills. Those people fuel the consumer spending that creates more opportunities to make things.

I feel that our country has outsourced too much manufacturing and I am pleased to see the trend reversing. Apple's announcements that the new models of their desktop computers will be built in Texas is both real and symbolic good news.

Trends away from mass production and toward personalized and personally configurable production also bode well for a manufacturing renaissance in the United States. The future of manufacturing will feature small work cells, equipped with 3D printers, close to the final consumers.

|

| Terri at the first Crane Paper site. |

What role do you feel manufacturing should have in the 21st Century United States?

You might also like:

Opportunity in Personalized Manufacturing

3D Printing Crosses an Inflection Point

Additive Manufacturing Pioneers

Thursday, June 20, 2013

Leap of Faith

|

| Eads Bridge in St. Louis. Image by Darkshark0159 |

Andrew Carnegie, whose Keystone Bridge Company had been subcontracted to build the bridge, decide to do something daring. The Eads bridge would be built of steel. When it opened in 1874, it was the longest arch bridge in the world and the first large bridge made from steel.

The bridge opened up the west to rail tavel. It also proved the value of structural steel which was soon used in the construction of bridges and buildings across the United States. The Carnegie Steel Company dominated the industry.

Carnegie took the leap of faith to build the bridge from steel. The confidence to take on enormous challenges is a common characteristic of great leaders.

Are you ready to jump?

You might also like:

Who Can Tell How Events Will Be Transformed

When Your Name Becomes an Adjective

If it's Worth Doing, Do it for Others

Thursday, June 13, 2013

Find Your Focus

|

| Standard Oil Refinery No. 1 in Cleveland, Ohio |

By keeping the primary focus on refining, the company was able to continually improve its processes and acquire other refining companies until the company eventually refined over 90% of the oil in the United States.

Standard Oil did acquire oil wells later and operated gas stations. But it was the intense focus on refining that made the other businesses possible. At the time it was broken up in 1911 by the Supreme Court for violations of the Sherman Anti-Trust Act, it controlled 70% of the refined oil market, but only 14% of the crude oil supply.

While diversification has some advantages, concentration is usually more successful.

How intense is your focus?

You might also like:

Not Too Hard, Not Too Easy

+50 Gamefulness

Focus for 2013

Thursday, June 6, 2013

All In

|

| Cornelius Vanderbilt |

In 1864, Vanderbilt sold the last of those ships and invested everything in the fledgling railroad industry. In the decade that followed, railroads transformed America and Vanderbilt became the wealthiest man in America.

When Vanderbilt saw the change happening in transportation, he didn't waste effort holding onto the past. He let it go and focused on the future.

What do you need to let go? Where do you need to be putting your full energy and resources?

You might also like:

Make a Not-to-do List

The Paradox of Excellence

Focus for 2013

Thursday, May 30, 2013

Own the Genre

|

| Ia Orana Maria by Paul Gauguin |

This was the third visit of my lifetime to the Met and it was a great joy to see some of my favorite paintings again and to watch Terri's reactions as she saw them for the first time. At one point, as we stepped into a room with several flower paintings by Georgia O'Keeffe, I commented that some artists have a style so unique you can recognize their work immediately.

That stuck in my mind as I reflected that a few artists master a particular technique or concentrate on a particular subject matter so intensely that they own the genre. Vincent van Gogh had his bold, thick paint strokes. Georges Seurat worked with dots. Edgar Degas captured the grace and energy of the dancers. Roy Lichtenstein also worked with dots, but in a completely different way than Seurat.

In the realm of photography there have also been those who have developed a style so unique it is instantly recognizable. Mathew Brady, Dorothea Lange, Ansel Adams and Annie Leibovitz come to mind.

Stepping beyond the visual arts, think of the companies that have so uniquely captured their niche that they own it in the minds of the consumer. Pullman railroad cars, Fender guitars, the Beatles, the Apple iPod and YouTube are a few examples.

What about you? What are you doing to find and claim ownership of your genre?

You might also like:

The Age of Creativity

Gateway to the Artistic

The Price of Canvas

Thursday, May 23, 2013

Creativity in Company Research

Philip Fisher, one of the pioneers of modern investment theory, identified fifteen points to look for in a common stock. The list begins with: Does the company have products or services with sufficient market potential to make possible a sizable increase in sales for at least several years?

That is a powerful question. But how do you find the answer? Imagine yourself as a new salesperson preparing to represent the company's products in a competitive market place.

One of the best places to begin is the company's website. Most sites have an "About Us" page which provides a brief history and stresses the core values of the organization. The product pages are usually categorized by market segments and teach the main features and benefits of the company's offering. The product pages are also a great way to learn the terminology and technology used in the company's offering.

Wikipedia is a good source of historical and technical information. Check out the entries on the company, the company founders and the technologies they developed. While the Wikipedia entries themselves are usually well organized and thoroughly hyperlinked, the references and external links at the bottom of each entry often lead to even more detailed and interesting articles.

Reading the company's most recent annual report is essential. In the annual report, the company officers share their point of view about the market they serve, trends in the marketplace, competitive strengths, and strategic plans for continuing growth. The annual report also contains the recent financial results which allow you to judge the success of the company's past decisions and if the company has the resources to implement the plans it has outlined.

After completing the research above, you would be ready to make your first sales presentation if yours were the only company in the industry. The next step is to identify each of the company's primary competitors and do a similar analysis on them. Review their web pages, read their product literature, learn their history of success and failure. Make sure you understand why your company and your products are better.

When you feel you understand the company well enough to make a sales presentation, you are in a good position to determine the quality of the investment. If you believe you could close the sale, the investment is worthy of consideration.

How do you analyze investment opportunities?

You might also like:

Stages of Investment

The Thrill of Ownership

Looking Forward

That is a powerful question. But how do you find the answer? Imagine yourself as a new salesperson preparing to represent the company's products in a competitive market place.

One of the best places to begin is the company's website. Most sites have an "About Us" page which provides a brief history and stresses the core values of the organization. The product pages are usually categorized by market segments and teach the main features and benefits of the company's offering. The product pages are also a great way to learn the terminology and technology used in the company's offering.

Wikipedia is a good source of historical and technical information. Check out the entries on the company, the company founders and the technologies they developed. While the Wikipedia entries themselves are usually well organized and thoroughly hyperlinked, the references and external links at the bottom of each entry often lead to even more detailed and interesting articles.

Reading the company's most recent annual report is essential. In the annual report, the company officers share their point of view about the market they serve, trends in the marketplace, competitive strengths, and strategic plans for continuing growth. The annual report also contains the recent financial results which allow you to judge the success of the company's past decisions and if the company has the resources to implement the plans it has outlined.

After completing the research above, you would be ready to make your first sales presentation if yours were the only company in the industry. The next step is to identify each of the company's primary competitors and do a similar analysis on them. Review their web pages, read their product literature, learn their history of success and failure. Make sure you understand why your company and your products are better.

When you feel you understand the company well enough to make a sales presentation, you are in a good position to determine the quality of the investment. If you believe you could close the sale, the investment is worthy of consideration.

How do you analyze investment opportunities?

You might also like:

Stages of Investment

The Thrill of Ownership

Looking Forward

Friday, May 17, 2013

Nothing Stationary in Stationery

|

| Shower Invitation from Paper Muse Press |

Like many industries, there is a steady shift taking place in the stationery market. The large social expressions companies including Hallmark and American Greetings are struggling to maintain their sales while smaller, more specialized companies are gaining market share. A birthday greeting on Facebook may be sufficient for casual acquaintances, but more important events are worthy of personalized cards from Tiny Prints, Minted or Paper Muse Press.

For most of the show, I will be working in a booth for Black River Imaging which is exhibiting for the first time at a stationery show. We are well known as a professional portrait lab, but more and more card companies have discovered that the printing, boutique packaging and drop shipping services that we provide for photographers are also a perfect fit for personalized stationery. Exhibiting at the National Stationery show will make it easier for these types of companies to find us.

The card samples that will be in the booth are from Paper Muse Press, a brand new social expressions company that just launched their web store this morning. It has been more than a year since Emily Walters, Rowena Raborar and Sarah Carney-Norris launched Paper Muse Press as a lifestyle blog featuring do-it-yourself decorating projects and some printable downloads. The blog posts are beautifully photographed and clearly explained.

In addition to blogging, the ladies of Paper Muse Press, and a talented team of design artists and web developers, have been working frantically behind the scenes to furnish their shop with over 3000 unique card designs that can be personalized with images, names and dates. Emily and Sarah will also be attending the National Stationery Show, so be sure to congratulate them if you run into them.

If you will be at the show in New York next week, come by booth 2888 and say hello.

You might also like:

Gateway to the Artistic

Print Can Be Art

Are You an Artist

Thursday, May 9, 2013

An Unforgettable Summer Job

In the summer of 1981, Carl Decker had completed his freshman year studying mechanical engineering at the University of Texas in Austin. He traveled to Houston for a summer job with a machine shop that made parts for the nearby oil fields. Many of the parts were made from castings which had to be shaped using handcrafted molds. Decker recognized the need for a method to automatically create castings from CAD drawings and began thinking of ways it could be done.

By the time he was ready to graduate, in 1984, he had developed the idea of using a beam of energy, such as a laser, to melt particles into a solid 3D object. He continued to work on the idea, developed the Selective Laser Sintering (SLS) process and formed the company DTM Corp which was sold to 3D Systems in 2001. SLS continues to be an important part of the 3D System product line.

Selective Laser Sintering is a 3D printing method that uses a high powered laser beam to fuse small particles of plastic, metal, ceramic or glass into a solid layer. After each layer is fused, the part is lowered, a new layer of powder is applied on top of the first layer, and the fusing process is repeated. The bulk powder in the SLS machine is preheated to nearly the fusing temperature to reduce the amount of laser energy required.

The most common uses for SLS technology are rapid prototyping, additive manufacturing of complex or low volume plastic parts and fabrication of casting patterns.

When the SLS process is used to manufacture metal parts, it is usually called Selective Laser Melting (SLM). The Swedish company Arcam AB has a similar system which replaces the laser beam with an electron beam and is appropriately named Electron Beam Melting (EBM). These processes are typically used to make parts for aerospace companies, personalized orthopedic implants and jewelry.

In 1993 Ely Sachs and Mike Cima of the Massachusetts Institute of Technology developed a process that uses a powder bed like SLS, but binds the powder with glue injected using a print head similar to an inkjet printer. The process, which they named 3D Printing (3DP), was sold to Z Corp which was acquired by 3D Systems in January 2012. Z Corp created the first full color 3D printer by combining color print heads with the binder print head.

The invention of the SLS process by Carl Decker after three years of reflection on the idea he originally formed during his summer job is a great example of the need to let ideas simmer to allow the brain to connect the dots in a new and unique way.

What's cooking in the back of your mind?

You Might Also Like:

Ideas are like Chili

The IDE3A Process

3D Printing Crosses an Inflection Point

By the time he was ready to graduate, in 1984, he had developed the idea of using a beam of energy, such as a laser, to melt particles into a solid 3D object. He continued to work on the idea, developed the Selective Laser Sintering (SLS) process and formed the company DTM Corp which was sold to 3D Systems in 2001. SLS continues to be an important part of the 3D System product line.

Selective Laser Sintering is a 3D printing method that uses a high powered laser beam to fuse small particles of plastic, metal, ceramic or glass into a solid layer. After each layer is fused, the part is lowered, a new layer of powder is applied on top of the first layer, and the fusing process is repeated. The bulk powder in the SLS machine is preheated to nearly the fusing temperature to reduce the amount of laser energy required.

|

| Selective Laser Sintering Diagram from Wikipedia |

The most common uses for SLS technology are rapid prototyping, additive manufacturing of complex or low volume plastic parts and fabrication of casting patterns.

When the SLS process is used to manufacture metal parts, it is usually called Selective Laser Melting (SLM). The Swedish company Arcam AB has a similar system which replaces the laser beam with an electron beam and is appropriately named Electron Beam Melting (EBM). These processes are typically used to make parts for aerospace companies, personalized orthopedic implants and jewelry.

In 1993 Ely Sachs and Mike Cima of the Massachusetts Institute of Technology developed a process that uses a powder bed like SLS, but binds the powder with glue injected using a print head similar to an inkjet printer. The process, which they named 3D Printing (3DP), was sold to Z Corp which was acquired by 3D Systems in January 2012. Z Corp created the first full color 3D printer by combining color print heads with the binder print head.

The invention of the SLS process by Carl Decker after three years of reflection on the idea he originally formed during his summer job is a great example of the need to let ideas simmer to allow the brain to connect the dots in a new and unique way.

What's cooking in the back of your mind?

You Might Also Like:

Ideas are like Chili

The IDE3A Process

3D Printing Crosses an Inflection Point

Thursday, May 2, 2013

Changing the World with a Glue Gun

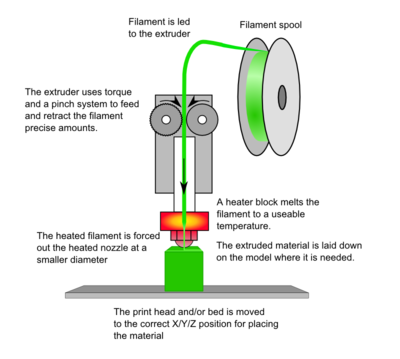

In 1989, Scott Crump wanted to make a toy frog for his two-year-old daughter. As he worked in the kitchen shaping the frog with a glue gun, he was also inventing the 3D printing process that would transform manufacturing in the 21st century. Crump formed Stratasys to commercialize the process he named Fused Deposition Modeling (FDM) and the company is now the largest manufacturer of 3D printers with a 44% market share.

FDM works by depositing droplets of melted thermoplastic in a computer controlled pattern much like a regular desktop printer jets ink.. The plastic solidifies after it is deposited to form one layer of a 3D object. When each layer is finished, the print head or print table are moved to allow the next layer to be added. This process is repeated layer after layer until the 3D item is completed.

The raw material for an FDM printer is typically a coil of plastic filament which is fed into a heating block to heat the end of the filament to the melting temperature. Stepper motors or servo motors move the print head to the precise x, y and z position to extrude each droplet.

Stratasys manufactures a wide range of FDM machines from desktop models for designers to large industrial models for manufacturing plants. Stratasys has a trademark on the term Fused Deposition Modeling and the abbreviation FDM so the RepRap, Makerbot and most other small 3D printers which use the same process refer to it as Fused Filament Fabrication or FFF.

The FDM process works with several types of thermoplastics including acrylonitrile butadiene styrene (ABS) polymer, polycarbonates, polycaprolactone, polyphenylsulfones and waxes making it suitable for a wide variety of prototyping and manufacturing applications.

You Might Also Like:

3D Printing Crosses an Inflection Point

Additive Manufacturing Pioneers

It Started with Stereolithography

FDM works by depositing droplets of melted thermoplastic in a computer controlled pattern much like a regular desktop printer jets ink.. The plastic solidifies after it is deposited to form one layer of a 3D object. When each layer is finished, the print head or print table are moved to allow the next layer to be added. This process is repeated layer after layer until the 3D item is completed.

The raw material for an FDM printer is typically a coil of plastic filament which is fed into a heating block to heat the end of the filament to the melting temperature. Stepper motors or servo motors move the print head to the precise x, y and z position to extrude each droplet.

|

| Diagram from RepRap Wiki |

Stratasys manufactures a wide range of FDM machines from desktop models for designers to large industrial models for manufacturing plants. Stratasys has a trademark on the term Fused Deposition Modeling and the abbreviation FDM so the RepRap, Makerbot and most other small 3D printers which use the same process refer to it as Fused Filament Fabrication or FFF.

The FDM process works with several types of thermoplastics including acrylonitrile butadiene styrene (ABS) polymer, polycarbonates, polycaprolactone, polyphenylsulfones and waxes making it suitable for a wide variety of prototyping and manufacturing applications.

You Might Also Like:

3D Printing Crosses an Inflection Point

Additive Manufacturing Pioneers

It Started with Stereolithography

Thursday, April 25, 2013

Who Can Tell How Events Will Be Transformed

|

| Taijitu by Nyo |

The Tao Te Ching contains the following parable:

A poor farmer's horse ran off into the country of the barbarians. All his neighbors offered their condolences, but his father said, "How do you know that this isn't good fortune?" After a few months the horse returned with a barbarian horse of excellent stock. All his neighbors offered their congratulations, but his father said, "How do you know that this isn't a disaster?" The two horses bred, and the family became rich in fine horses. The farmer's son spent much time riding them and one day fell off and broke his hipbone. All his neighbors offered the farmer condolences, but his father said, "How do you know that this isn't good fortune?" Another year passed, and the barbarians invaded the frontier. All the able-bodied young men were conscripted, and nine-tenths of them died in the war. Thus good fortune can be disaster and vice versa. Who can tell how events will be transformed?*

I don't know how things are going to turn out and neither do you. In the absence of a personal Tardis, we can only travel the stream of time in one direction. Our best option is to move forward with the understanding that we will encounter obstacles and the confidence that we will overcome them.

You might also like:

Rainy Days and Mondays

When Your Name Becomes an Adjective

Looking Forward

*Tao Te Ching, Chapter 74, translated by Stephen Mitchell

Tuesday, April 16, 2013

The Paradox of Certainty

|

| Probability Stories by Iruhdam |

policy change is the result of a chaotic interplay between millions or

billions of individuals acting in ways that may not always be

rational. The probability of any particular result is almost never 0%

or 100%.

Whenever I hear a talk radio host or television commentator

belligerently proclaiming the certainty of their particular view of

the future, I wonder whether they haven't thought things through

carefully or they're just being dishonest.

You might also like:

Changing the Odds

Collision of Ideas

Choose the Difficult Assignment

Thursday, April 11, 2013

Postcards from the Netherlands

A couple of weeks ago, I traveled with my wife Terri and daughter Jennifer to visit our daughter Amy who is studying international law in the Netherlands. That's Amy above with her mentor Hugo Grotius, the "Father of International Law."

Amy lives just a few steps away from this beautiful canal in central Utrecht.

A bicycle is one of the best ways to get around the city center, but you have to park it somewhere. This parking area is near the Utrecht central train station.

It's easy to know what time it is in Utrecht. It was nine o'clock when we walked past the Dom Tower and its bells began to ring.

We took a weekend trip to Maastricht where it had snowed the day before. This water channel which feeds the moat surrounding the old town walls no longer has much defensive value. But it's great for a quiet walk.

The Maastricht Town Hall, which was across the square from our hotel, looks a little eerie in the moonlight.

I was surprised to see this in a shop window on the square in Maastricht.

When we returned to Utrecht, we were able to take a walk with these gigantic snowflakes falling. I particularly like the way the orange backpack contrasts with the dull colors of the cobblestones and bricks.

We had a wonderful time exploring the Netherlands with Amy and Jennifer. Where are you planning to vacation this year?

You might also like:

Inspired by WPPI

Wide and Wonderful

November in Columbia

Thursday, April 4, 2013

It Started with Stereolithography

|

| Stereolithography diagram from Wikimedia Commons |

The first 3D printer was developed by Charles Hull in Valencia, California in the 1980s. He first used the term stereolithography in his patent entitled “Apparatus for Production of Three-Dimensional Objects by Stereolithography” issued on March 11, 1986. Hull later relocated to Rock Hill, South Carolina and formed the company 3D Systems to manufacture the 3D printers.

Stereolithography works by sweeping an ultraviolet laser beam across a vat filled with a liquid photopolymer resin. Where the laser beam hits the resin, it solidifies to form one layer of a solid part. The part is lowered by a distance of .05mm to .15mm and a resin filled blade sweeps across the part to coat it with a fresh layer of liquid resin. This layer is also solidified by the ultraviolet laser and the process is repeated, layer by layer, until the full 3D part is completed. After printing, the parts are submerged in a chemical bath to remove any excess resin and cured in an ultraviolet oven.

The .stl file format, which is often used to store 3D dimensional data, was also developed by Hull to enable the transfer of the shape data into the stereolithography machines.

Stereolithography was originally intended to accelerate the engineering process by allowing the creation of rapid prototypes and is still used primarily for that purpose. The process is also used to make molds for investment casting. The machines are typically large, expensive and produce parts with extremely high resolution and accuracy.

You might also like:

3D Printing Crosses an Inflection Point

Additive Manufacturing Pioneers

Focus for 2013

Wednesday, March 13, 2013

Inspired by WPPI

|

| Photography by Whitney and David Scott |

Today I am flying home from Las Vegas where I have spent the last four

days in the Black River Imaging booth at the WPPI Wedding and Portrait

Photographers Conference and Expo. Over 16,000 professional and

aspiring professionals attend this conference every year to improve

their skills and network with their peers.

The thing that impresses me most about WPPI is the energy level. The

people who attend the WPPI convention are passionate about photography

and eager to learn more. Those who have been in the industry for years

are enthusiastic about sharing their experiences and excited to learn

more. The event is particularly supportive to those just getting

started in the industry.

|

| Photography by Corrine Alavekios |

I have been attending WPPI since the early 1990's when the show was

tightly focused on wedding photography. It has been exciting to watch

it grow and expand to cover birth, preschool, sports and fashion

photography as well as wedding and family portraits. The classes

cover everything from lighting and posing to business planning and

law.

Black River Imaging has changed a lot since the 1990s too. In those

days the images were all captured on film which was processed on giant

dip and dunk Refrema machines. We used Lucht V7 printers to make any

print size you wanted. Today the book and album binding areas are

bigger than the print room and our fastest growing product lines are

luxury stationery and wall decor printed on metal.

|

| Photography by Amanda Reed |

I really enjoy meeting with our customers during the trade show. It's

a perfect venue to learn what we're doing well, where we need to

improve and what kind of new products people want. We introduce new

products continuously, and the conversations we have during the show

influence every product development meeting.

The Black River imaging booth is divided into two sections. Half the

booth is used to display products including the new lay flat picture

books and the LOFT line of luxurious cards and stationery. The

products that draw the most attention are usually those that have rich

textures and unique shapes.

|

| Photography by Dawn Shields |

The other half of the booth is dedicated to education. The Black River

Imaging featured artists, whose images accompany this post, teach a

series of classes about photography and the business of photography.

I always leave WPPI inspired, invigorated and looking forward to

coming back next year.

|

| Photography by Dixie Dixon |

|

| Photography by Elise Ellis |

|

| Photography by Martha Dameron |

|

| Photography by Spencer Beorup |

|

| Photography by Vanessa Joy |

You might also be interested in:

Five Trends in Professional Portraits

Trends in Professional Portraits at Imaging USA

Sincerely Social

The Creativity Paradox will be taking a break from publishing for the next two weeks. Please look for our next post on April 4th.

Thursday, March 7, 2013

Stages of Investment

|

| Books by Zen Oracle |

Invest in Learning a Trade

In the beginning, select a skill you love doing and learn to do it extremely well. Enroll in the classes required and study diligently. In the workplace, identify the best people in your field and try to emulate their techniques. Read all of the books, manuals and trade publications that are relevant. Most of all, practice constantly with the goal of becoming better everyday.

While you are investing your thought and energy in learning a trade, remember to save five to ten percent of every paycheck. You will need it later.

Invest in Learning to Lead

There is a limit to what you can accomplish by yourself. The most skilled craftsman in the world is limited to what can be completed by a single pair of hands in a day. If you want to achieve more, you must learn to lead others.

Leadership requires knowledge, optimism and empathy. Knowledge is important because people won't follow someone who is obviously wrong. Optimism matters so it is clear that you believe the mission is possible. Empathy is critical because people don't care how much you know until they know how much you care. It needs to be obvious that you care about the mission, the organization and about them.

While much of leadership is a state a mind, it is also a learned skill. Pay attention to the leaders you admire and watch how they do it. Even if you feel you have a deep understanding of your field, this is not the time to cease learning. Continue to study the new developments in your field, but broaden your reading to include techniques in management and leadership and the biographies of great leaders.

By now, saving five to ten percent of your earnings should be a habit and your savings are beginning to accumulate. A stock mutual fund is the easiest way to ensure a return higher than the rate of inflation.

Invest in Learning to Own

For those fortunate enough to grow old, there will come a time when they no longer have the interest or perhaps the ability to actively lead every day. At that point, independence and security come through ownership. Companies pay dividends and continue to appreciate in value without constant supervision.

When looking ahead to this stage of life, it is important to make sure that the savings accumulated are deployed where they can earn the most. Unfortunately this is a difficult skill to learn because most of the recommendations in the news and most professional advice is wrong. As in the other stages, pay attention to the methods of those who have been successful: Shelby Davis, Warren Buffet, Peter Lynch.

Read the books, learn the basics and apply the wisdom acquired over your lifetime to develop a methodology and style that works for you.

Study is the Constant

Amazon probably appreciates this post because the one thing is remains constant through all of these stages is reading and learning. One of the books I am currently reading is Team of Rivals: The Political Genius of Abraham Lincoln by historian Doris Kearns Goodwin. One of the most remarkable traits of our greatest President is that he never stopped reading and never stopped learning.

What are you learning this week?

You might also like:

The Age of Creativity

Do Your Own Annual Review

The Thrill of Ownership

Thursday, February 28, 2013

You Would Even Say it Glows

|

| New Fire and Ice by Thomas Mangelsen |

A few weeks ago, a friend asked me to take a look at

the images at the Thomas Mangelsen Images of Nature gallery in Las Vegas. These

images are not only visually stunning, they also seem to change with

different light levels and the gallery exhibited some of them in a

room with a dimmer to demonstrate this effect.

Most

of the images in the gallery were printed on silver halide photo

paper laminated to the back of a sheet of acrylic. This is a

beautiful way to mount a photographic print, but most of the visual

impact, including the interesting effect with the dimmer, was in the

original photography. These images will exhibit similar

characteristics when printed on high gloss metal or any other method

which has crisp and vibrant color reproduction.

|

| Cypress Sunset by Thomas Mangelsen |

This

style of photography draws characteristics from a group of American

painters in the mid 1800s who painted landscapes and seascapes that

were infused with light. These “luminist” painters created works

that radiate light, whether from a window of a stone cottage or

through shafts of sunlight penetrating through the clouds. This was

was a favorite technique of the Hudson River School and was

incorporated into western landscapes by Albert Bierstadt and others.

|

| Between the Sierra Nevadas by Albert Bierstadt |

Luminism

strongly influenced the popular “Painter of Light” Thomas Kinkade

who called his use of light the “Kinkade Glow.” He has explained

that his method for creating the glow relies on three visual aspects:

“soft edges, a warm palette and an overall sense of light.” The

effect is particular effective for Kinkade in suggesting romanticism

and nostalgia with a sense of mystery.

|

| The Beginning of a Perfect Day by Thomas Kinkade |

To

emulate the Luminist style, your image should contain saturated

pastels, particularly the warmer shades of yellow and orange. The

edges of the image can be darker so the eye is drawn to the main

source of light and the reflections the light creates.

After

becoming familiar with this style of painting and photography, I

decided to dig through my own image archives looking for examples. I

believe these images of a sunrise over the Indian Ocean, which my wife

Terri captured last year in Mozambique, fit the description perfectly.

|

| Indian Ocean Sunrise One by Terri Williams |

|

| Indian Ocean Sunrise Two by Terri Williams |

I had some of these printed by Black River Imaging on 16x20 metal and tested the effect with

a light and dimmer in my dining room. The pictures really do change dramatically as the light level changes.

Try it for yourself and

see what you think!

You might also like:

Subscribe to:

Posts (Atom)